Need Specifications or a Quote?

Share your ventilation project requirements and our engineers will reply within 12 hours with technical specs, pricing, and lead time.

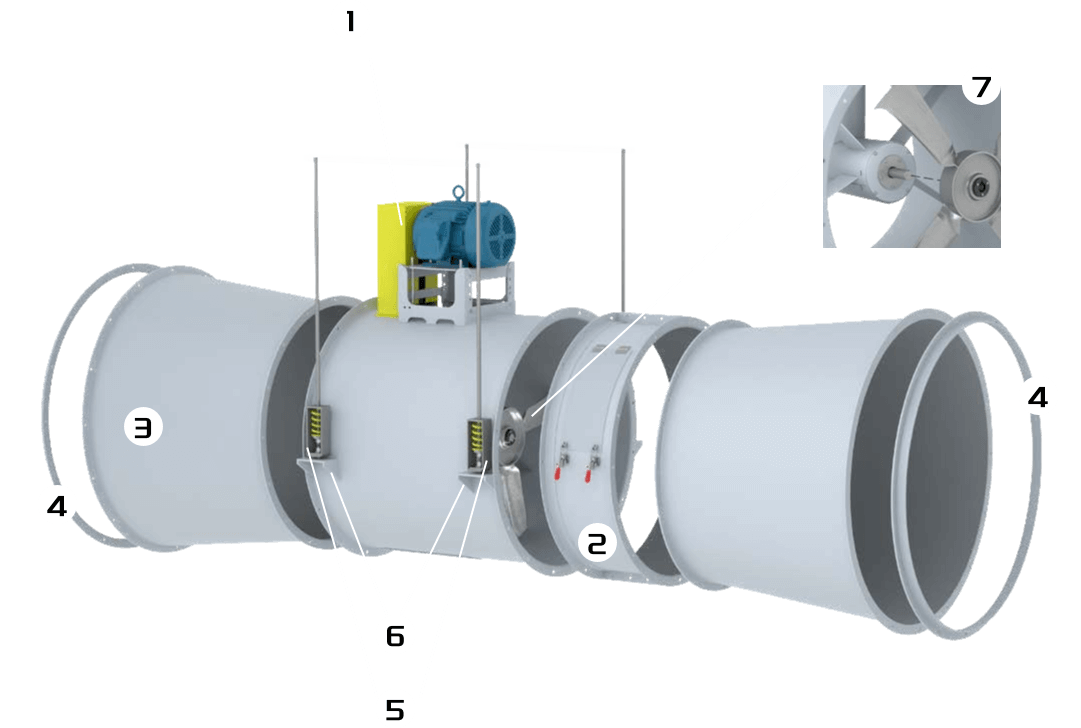

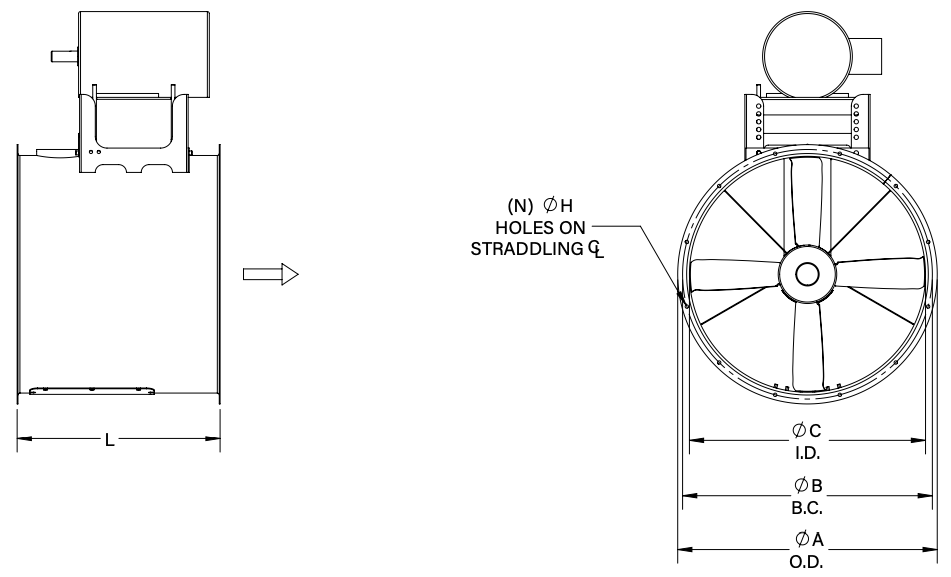

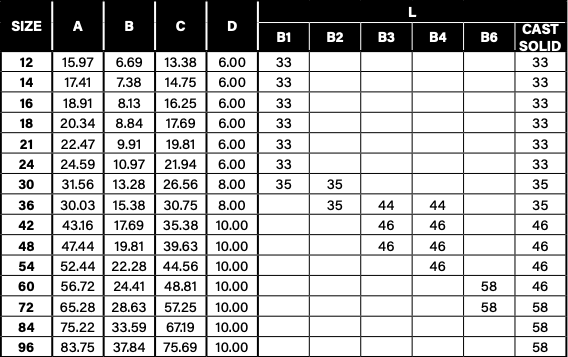

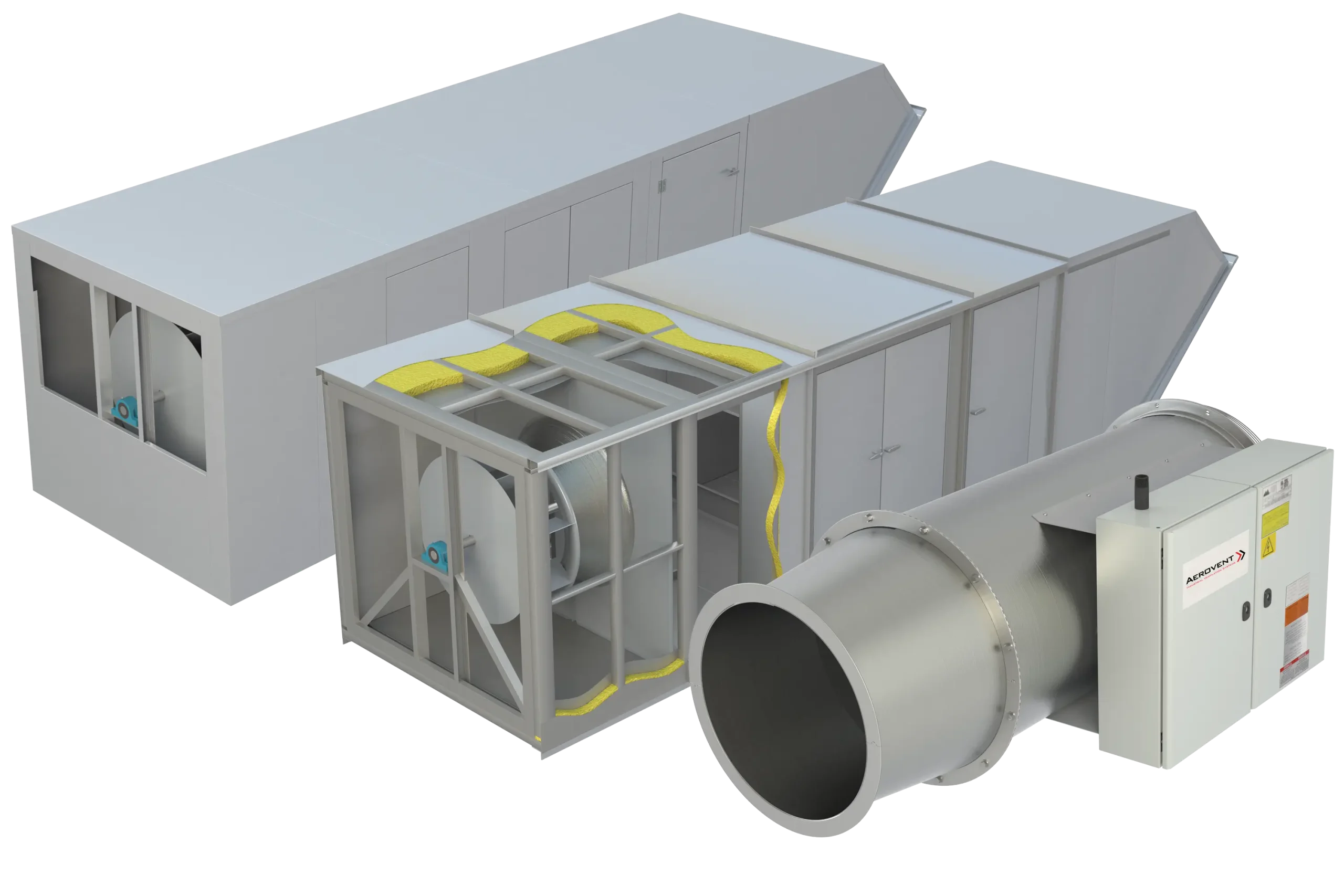

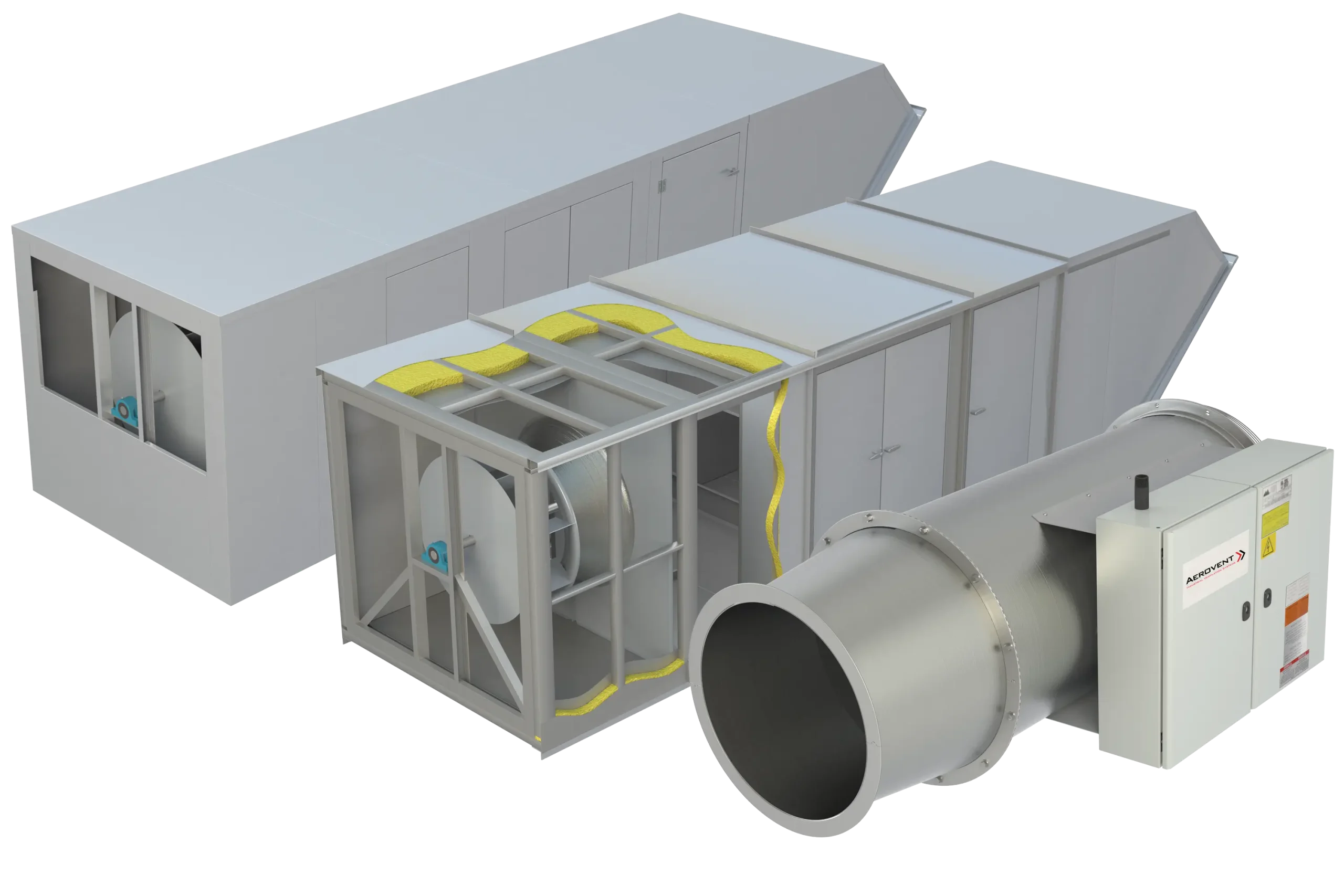

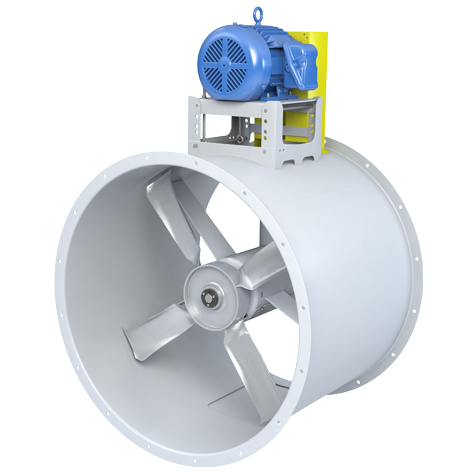

Engineered for tough airstreams, this tubeaxial fan handles corrosive fumes, smoke, and hot or humid air with confidence. A tipped, cast‑aluminum airfoil blade boosts efficiency and airflow, while the continuously welded, heavy‑gauge flanged housing includes pre‑drilled bolt holes for fast, secure mounting to accessories or ductwork. All impellers and hubs are standard 319 aluminum. Impellers from 14 to 72 inches are solid cast, while 84-inch and larger models feature an adjustable‑pitch design with individual blades and a central hub.

Size

Airflow

Static pressure