Rectangular vs Spiral Ducts: Airflow Efficiency, Cost, and Installation Differences

Introduction: Why Duct Shape Matters in HVAC Systems

When designing or evaluating an HVAC ventilation system, the duct shape plays a crucial role in airflow efficiency, installation feasibility, energy performance, and overall system cost. Among the most common duct configurations, rectangular ducts and spiral ducts are widely used in commercial, industrial, and infrastructure projects. While both perform the same basic function—transporting air—each has different structural characteristics, manufacturing advantages, and performance outcomes.

Choosing between rectangular and spiral ducts is not merely a matter of project preference. It involves evaluating spatial constraints, pressure drop, leakage control, noise level, manufacturing capabilities, and installation logistics. This article compares rectangular and spiral duct systems in detail to help contractors, designers, and procurement teams make informed decisions for real project environments.

1. Overview of Rectangular and Spiral Ducts

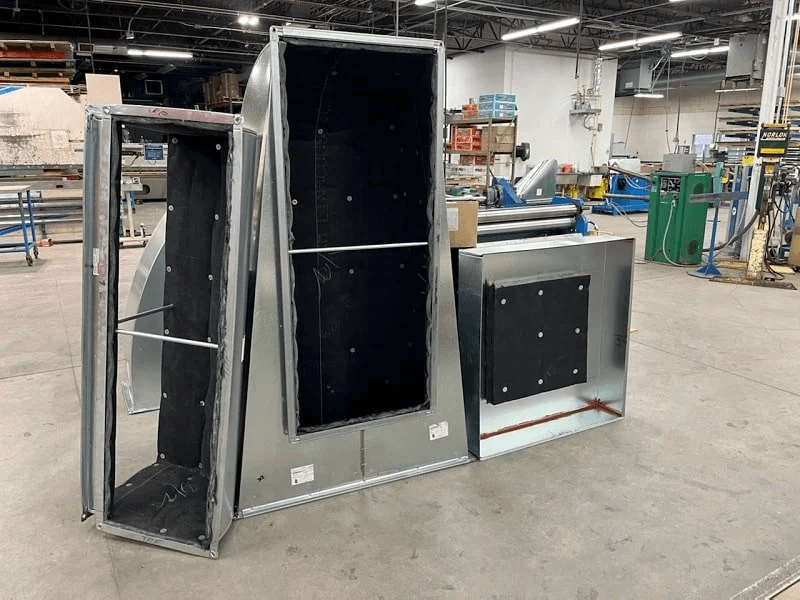

Rectangular Ducts

Rectangular ducts are fabricated from sheet metal into a four-sided profile and are commonly used in commercial buildings where ducts must be installed close to ceilings, walls, or structural beams. Their flat geometry allows easy stacking and routing through narrow ceiling cavities.

Learn more: Rectangular Duct and Fittings

Spiral Ducts

Spiral ducts are manufactured as round cylindrical sections formed by spiral-wound sheet metal. Their continuous shape provides structural rigidity, smoother airflow, and lower leakage rates. Spiral ducts are often used in open ceilings, warehouses, industrial plants, and areas where airflow efficiency is prioritized.

Learn more: Spiral Duct and Fittings

2. Airflow Efficiency and Pressure Drop

Airflow resistance (pressure drop) is a key consideration when selecting duct shape. The internal geometry of the duct affects turbulence, friction, and required fan power.

Spiral Ducts: Smoother Airflow

- Round cross-sections promote uniform airflow.

- Reduced friction loss along the duct walls.

- Fewer internal corners where turbulence can develop.

Because spiral ducts reduce pressure drop, they often allow smaller fan power requirements and lower operating energy consumption, especially in large-volume ventilation systems.

Rectangular Ducts: Higher Friction and Turbulence

- Corners cause turbulence and friction.

- Pressure loss increases with aspect ratio (very wide or very narrow ducts perform worse).

- Additional internal reinforcement may be required for larger duct sizes.

This does not mean rectangular ducts are inferior—only that they must be appropriately sized and installed to maintain performance.

3. Space Constraints and Installation Considerations

Rectangular Ducts Fit Better in Confined Spaces

Rectangular ducts are often chosen because they fit into architectural constraints:

- Shallow ceiling voids where height is limited.

- Areas requiring ducts to run tightly along walls or beams.

- High-density mechanical rooms.

They can be dimensioned to match available space, which makes them flexible for renovation projects.

Spiral Ducts Require More Vertical Clearance

Spiral ducts require ceiling depth to maintain circular geometry. However, when exposed, they provide:

- Clean industrial aesthetic for open-ceiling design.

- Minimal need for insulation paneling or enclosure.

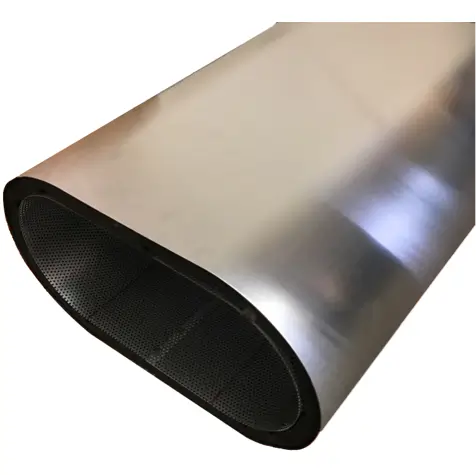

A Middle Ground: Flat Oval Ducts

When airflow efficiency of round ducting is needed but height clearance is limited, flat oval ducts are an effective compromise. They maintain many aerodynamic advantages of spiral ducts while fitting into shallow ceiling areas.

Learn more: Flat Oval Duct and Fittings

4. Leakage Control and Energy Performance

Air leakage is a major contributor to HVAC system inefficiency. Leakage occurs at joints, seams, and flanges.

Spiral Ducts Have Lower Leakage Risk

- Continuous seam reduces joint count.

- Factory-formed gaskets improve sealing consistency.

- Fewer connection points lower risk of installation errors.

Rectangular Duct Sealing Quality Varies More

- Multiple panel seams require careful joint sealing.

- Corner and flange systems introduce more potential leak paths.

- Performance depends heavily on installation workmanship.

5. Sound and Vibration Control

Airflow turbulence and duct vibration contribute to noise levels.

Spiral Ducts Reduce Noise Naturally

The circular profile creates more stable airflow, producing less turbulence noise. Additionally, spiral ducts can be fitted with internal liners for acoustic control.

Rectangular Ducts May Require More Acoustic Treatment

Because of turbulence at corners and flat wall resonance, rectangular ducts often require external insulation or internal lining to achieve similar acoustic performance.

6. Manufacturing and Fabrication Considerations

Manufacturing capabilities also influence duct selection.

Rectangular Ducts

- Flexible sizing for architectural constraints.

- Requires sheet metal cutting, bending, and flange assembly.

- Large ducts require internal reinforcement.

Spiral Ducts

- Continuous forming process provides consistent rigidity.

- Lower steel thickness may be used due to shape strength.

- Reduced need for stiffening and support.

For custom geometries, see: Custom Metal Fabrication

7. Cost Comparison

Costs vary depending on material, size, labor rate, shipping distance, and insulation requirements.

| Factor | Rectangular Duct | Spiral Duct |

|---|---|---|

| Material Efficiency | Less efficient sheet usage | More efficient material utilization |

| Fabrication Labor | Higher due to flange and seam assembly | Lower due to continuous forming |

| Installation Time | Slower, more parts | Faster, fewer joints |

| Insulation | Usually external | Can use double wall acoustic lining or internal liner |

8. Application Recommendations

Use Rectangular Ducts When:

- Ceiling height is limited.

- Ducts must run flush to walls or beams.

- Architectural concealment is required.

Use Spiral Ducts When:

- Energy efficiency and pressure reduction are priorities.

- Open ceiling or industrial aesthetic is desired.

- Long duct runs are needed (fewer joints, less leakage).

9. Conclusion

Both rectangular and spiral ducts are effective HVAC air distribution solutions when applied correctly. The choice depends on building geometry, airflow efficiency requirements, installation environment, and long-term operating cost considerations. Understanding the performance and construction characteristics of each duct type allows better planning and system optimization.

Project Consultation

If you have project drawings or duct specifications, our engineering team can assist with product matching and fabrication planning.