Need Specifications or a Quote?

Share your ventilation project requirements and our engineers will reply within 12 hours with technical specs, pricing, and lead time.

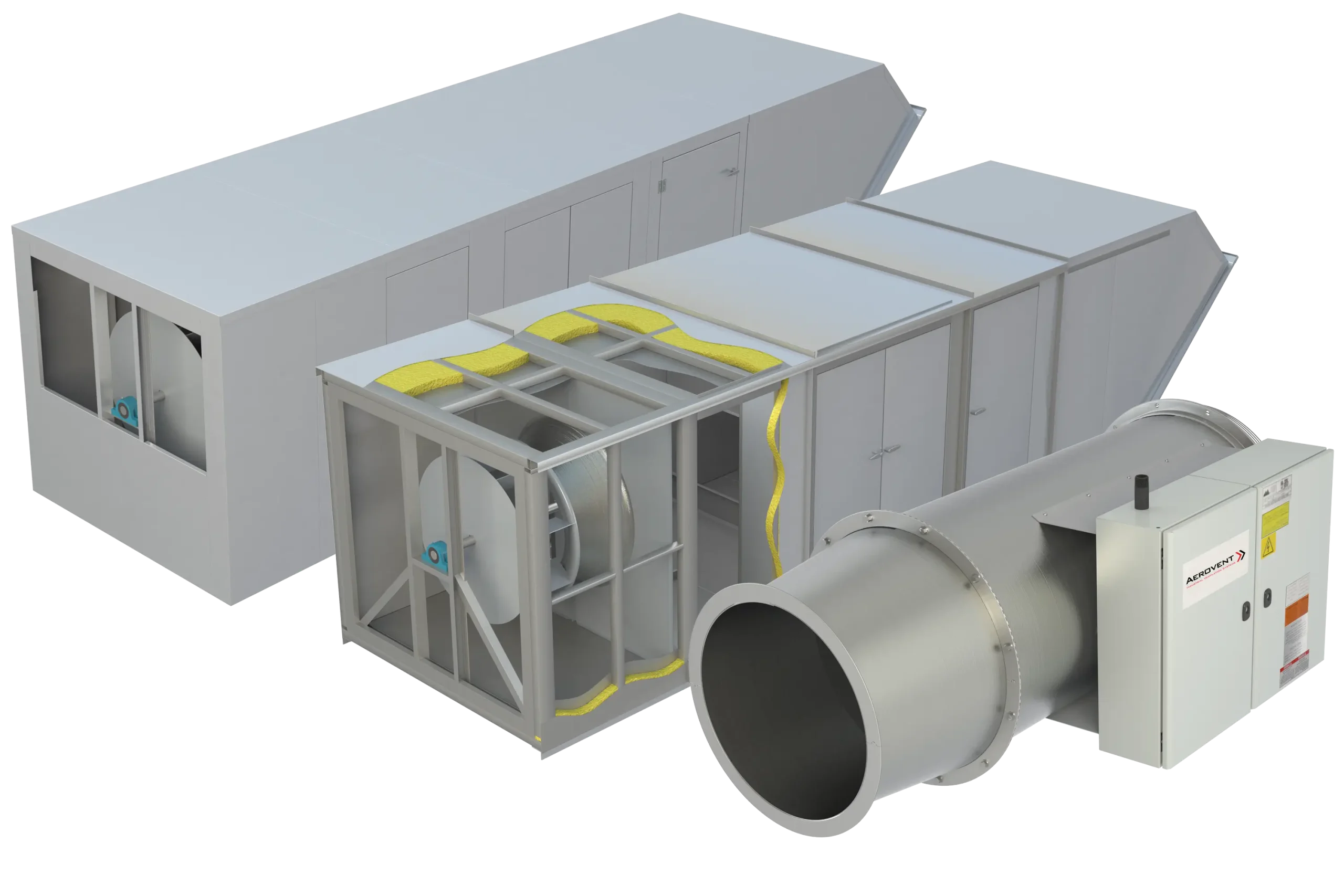

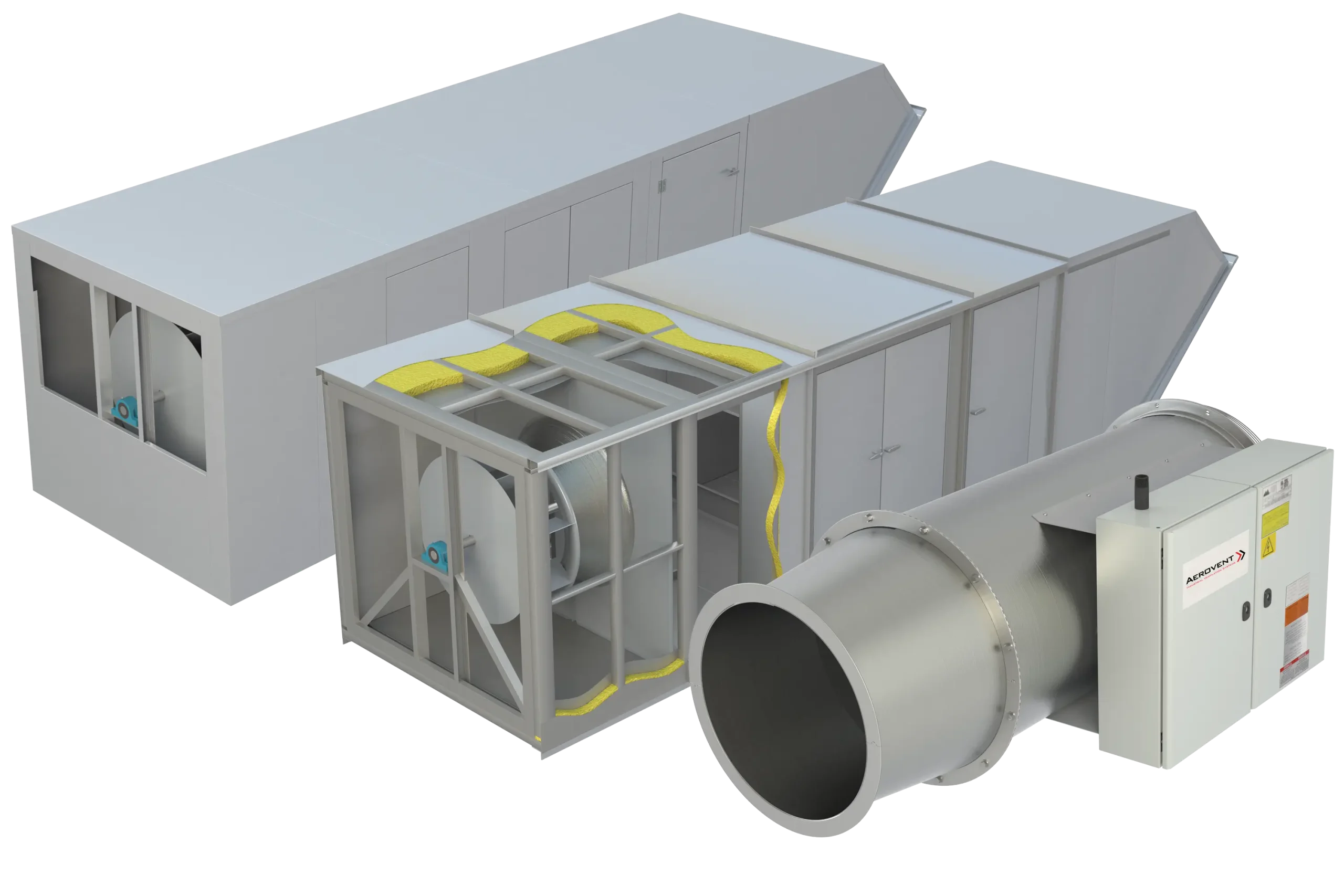

The Double Wall Rectangular Duct is designed for HVAC systems that require both thermal insulation and sound attenuation. It consists of two layers of galvanized steel with an insulation layer—typically glass wool or rock wool—sandwiched between them.

This dual-wall design prevents heat loss, minimizes noise transmission, and eliminates condensation, ensuring efficient and quiet airflow for commercial and industrial buildings. Key Specifications

Material: Inner & outer galvanized steel sheets

Insulation: Glass wool or rock wool (25–50 mm)

Sheet Thickness: 0.5–1.2 mm per layer

Standard: SMACNA / DW144 / ISO 9001

Connection Type: TDC, TDF, Flange, or Slip Joint

| Inner Wall | Galvanized steel (G90 / DX51D+Z) |

|---|---|

| Outer Wall | Galvanized steel (G90 / DX51D+Z) |

| Insulation | Glass wool / rock wool / foam board |

| Insulation Thickness | 25–50 mm (optional) |

| Sheet Thickness | 0.5–1.2 mm (per layer) |

| Connection Type | TDC / TDF / Flange / Slip Joint |

| Standard Length | 1000–1500 mm per section |

| Leakage Class | SMACNA Class 3 or higher |

| Standards | SMACNA / DW144 / ISO 9001 |